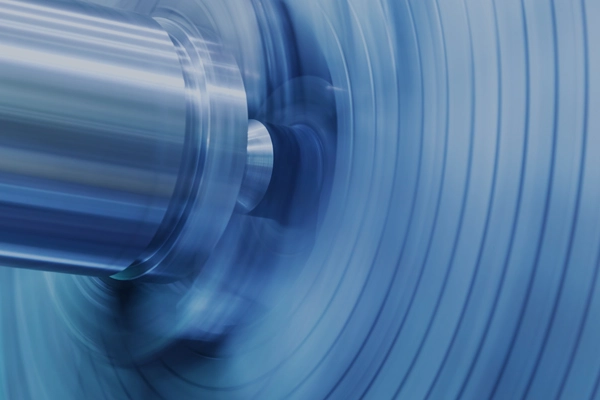

Dynamic Balancing Services

The know how, experience and equipment necessary to design and manufacture the most sophisticated balancing tooling affords us the ability to also offer the highest level balancing services. We specialize in dealing with balancing jobs other shops would rather not attempt.

Jobs entrusted to us include research and development of new rotors, balancing of difficult medical and aerospace parts often involving tight tolerances with high levels of repeatability, small ultra high-speed motor armatures and spindles and, any project where cleanliness is a concern.

Trusted by

NextGen offers the highest level of balancing services and tooling for a wide variety of parts.

4111276

4111549

4111563

4119954

4119955

30G5606

31G0009

ITAR Registered

SAE ARP 4048 & 4050 Certified

Pratt & Whitney BSQ Approved

To get started with your next balancing and/or tooling project, contact us online or by phone at sales@ngbalancing.com, (802) 585-1323 or by using our contact form.