Design

Manufacture

Balance

ON-SITE MANUFACTURING CAPABILITIES

Capabilities

Surface Grinding / Flat Lapping

EDM (wire and sinker)

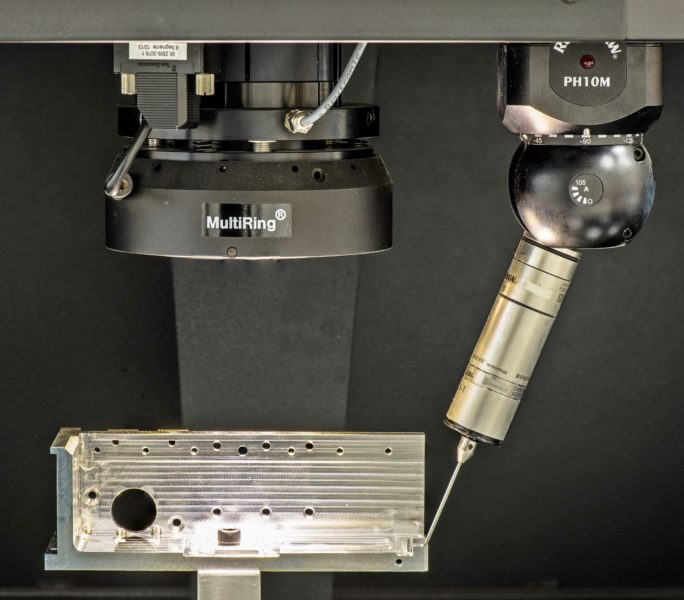

Metrology lab -CMM, optics and laser scanning capabilities

Manufacturing Engineering

Electro-Mechanical Assembly

Research and Development

Prototypes (low to high volume)

Testing

Tooling and Fixturing

Manufacturing, Refurbishment and Re-certification

Computer Aided Design (CAD)

Computer Aided Manufacturing (CAM)

KANBAN – inventory control, management, fulfillment and distribution

Material Expertise

Ceramics and other hard brittle materials: Macor, alumina, quarts, Zurodur and, silicon carbide.

Plastics: Peek, Torlon, Delrin, CPVC, Teflon and others including carbon and glass filled ceramics.

Machining

2 – Okuma Genos M560-V 3 & 5 Axis Machining Centers

3 – HAAS VF3YT, 5 Axis Machining Centers

3 – Haas VF2: 1 x 5-Axis, 1 x 4-Axis, 1 x 4- Axis with 55,000 RPM Spindle

2 – HAAS MDC 500 Pallet Changers (both 5 Axis)

1 – AgieCharmilles Form 30 Sinker EDM

1 – AgieCharmilles Cut 30 Wire EDM

1 – Haas Office Mil

1 – Haas Toolroom Mill 2

1 – Haas Toolroom Lathe

1 – Okamoto Surface Grinder Magnetic Chuck

Inspection

Clean Room